PHONE

▼product usage

contact, connector, micro screw

タップして拡大

タップして拡大

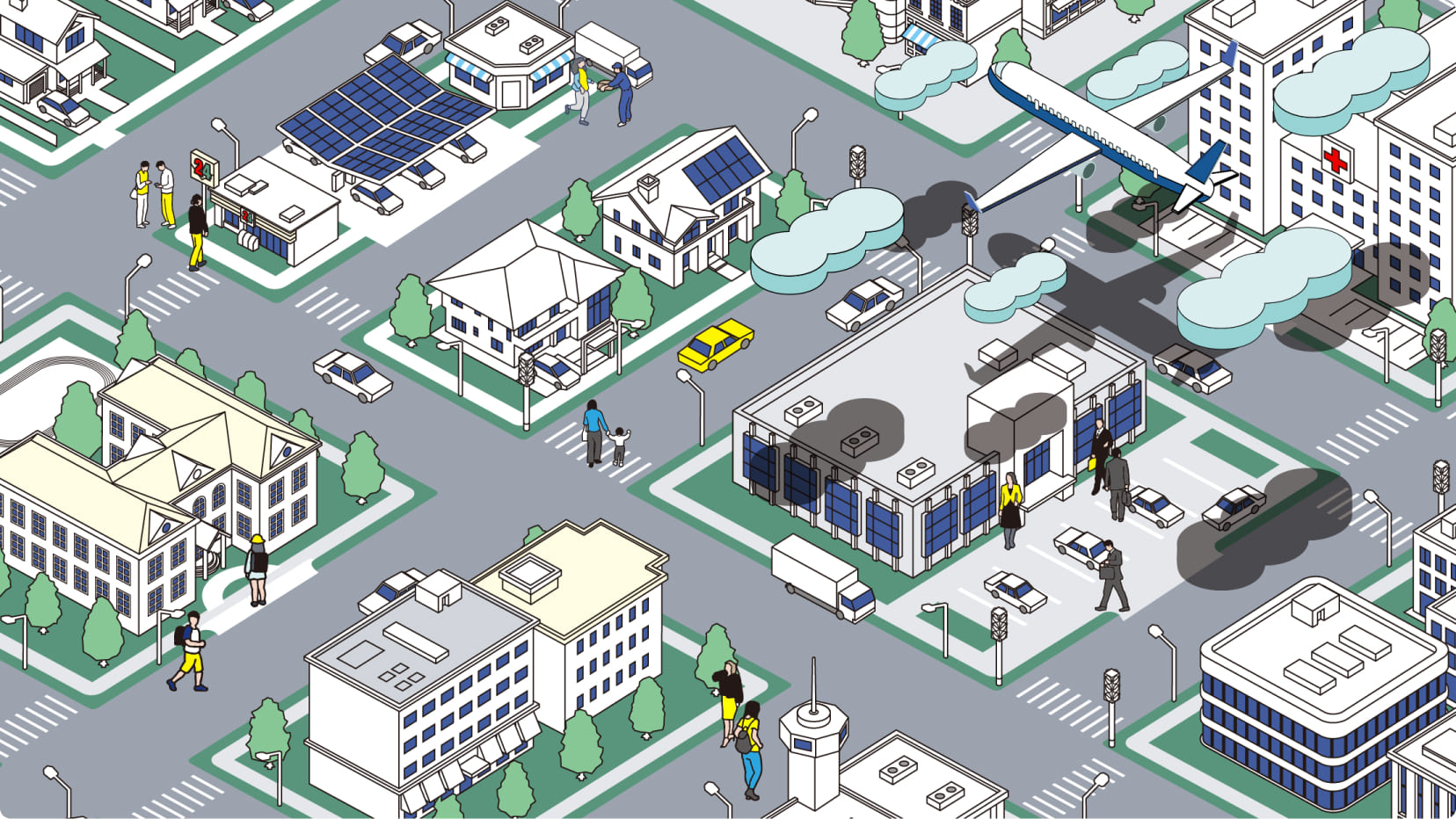

Nakashimada takes pride in its world-leading technical expertise and market share in the field of header former manufacturing—a machine used to produce screws and bolts, essential components found in wristwatches, mobile phones, automobiles, aircraft, and various other industrial products. We have absolute confidence in meeting the precision requirements, specifically the roundness, demanded by screws and bolts.

Founded in 1911 (Meiji 44) in Kurume City, Fukuoka Prefecture, Nakashimada initially specialized as a manufacturer of precision machine tools. Leveraging our accumulated expertise, we developed our first high-performance domestic header in 1960 to compete with imported machines. In 1969, we introduced the "2D3B" series, which garnered global attention for its groundbreaking mechanism, high precision, and superior productivity. Since then, we have consistently responded to increasingly complex and advanced demands with original technology and a comprehensive production system, continually releasing high-performance Header and Former. Additionally, Nakashimada's ongoing development of various new models, utilizing proprietary technology to achieve high precision, continues to underpin advancements in the industrial sector.

At Nakashimada, we provide total support from machine design and manufacturing to installation and after-sales service.

Please contact us by phone or through the inquiry form. If you can provide us with the drawings of the products you plan to manufacture, we will be able to assist you more smoothly.

Skilled engineers will review the received part drawings, select the appropriate model, and choose the necessary options.

After placing an order, our sales representative will conduct detailed discussions regarding the specifications. We will actively propose specifications from our side to ensure efficient production of the product. Please feel free to communicate any requests, including tooling development, to us.

Based on the specifications determined during the meeting, skilled engineers will carry out precise and reliable part fabrication, as well as machine assembly and adjustment. Leveraging their extensive experience and expertise, they will accommodate a wide range of requirements.

We also offer pre-shipment inspections and operator training according to your requirements. If necessary, we can also provide installation services for the machinery.

We provide support tailored to your needs, including post-shipment maintenance,

readjustment due to facility relocation, and supply of aftermarket parts.